![BMBF_CMYK_Gef_M [Konvertiert]](https://www.bit-ts.com/wp-content/uploads/2019/10/BMBF_gefoerdert_2017_en.jpg)

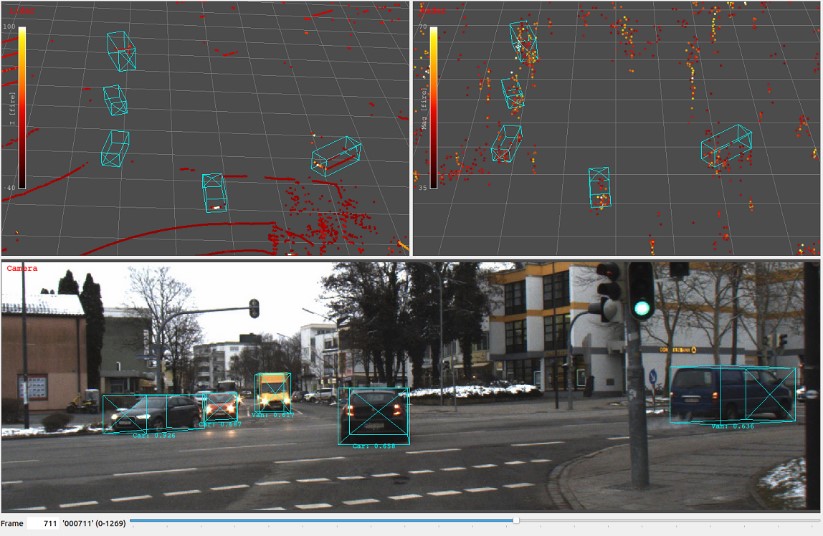

Automated and fully automated vehicles must independently capture and understand their environment. In heavy rain or snow, however, sensors such as cameras and lasers are blind. In such weather conditions radar systems perform significantly better.

In the AuRoRaS project (Automotive Robust Radar Sensing) project, three partners from research and technology are working on improving the measurement quality of high-resolution radar sensors. As part of the funding program KMU-innovativ of the Federal Ministry of Education and Research (BMBF), new simulation methods and methods of artificial intelligence are to be developed in order to make radar systems more efficient and autonomous driving safer.

In the next two years, the Astyx GmbH (project coordination), the BIT Technology Solutions GmbH and the German Research Center for Artificial Intelligence (DFKI) will realize an automotive radar system for use in highly automated (Level 4) and autonomous driving (Level 5). With its research and developments, the consortium wants to significantly increase the quality of the measurement data of the so-called continuous wave radar. With this radar technology radar signals are radiated uninterrupted during the measurement and the reflections are measured.

Radar sensors are already widely used in the automotive industry. The big advantage over camera-based methods or laser sensors (Lidar) is the direct measurement of the object speed and the robustness against weather influences such as fog or snow. Disadvantages are possible errors in the signal processing which can arise due to speed ambiguities or the so-called multipath propagation – for example due to the reflective road surface. In automated or autonomous driving functions, however, a very high accuracy and robustness is imperative. In the project, the physical disadvantages of radar sensors are to be identified and eliminated by innovative AI methods.

High-resolution radars and software-based object recognition

In addition to its high-resolution radar devices, Astyx GmbH also contributes the specialist knowledge in software-supported object recognition. This know-how in 3D object recognition from radar point clouds and deep learning-based object recognition will be used to improve the AI-based point cloud extraction from the radar raw data. In addition, Astyx develops synchronized data logging, geometric calibration of the sensors and the development of data interfaces and tools for annotating the real test data.

Simulation of radar data

BIT Technology Solutions GmbH develops a synthetic, physically based simulation of the radar sensor data as well as the required reference data (ground truth). This simulation environment serves as the basis for a scalable and efficient training of the AI and the qualitative validation of the AI algorithms. The concept of BIT Technology Solution GmbH enables research in the simulation of the entire spectrum of electromagnetic waves and the subsequent generation of corresponding synthetic data for training and validation. The combination of simulated and real radar data significantly improves the accuracy and robustness of the AI methods used to clean up the measurement data and thus the environment detection of an autonomous vehicle based on it.

Feature extraction with deep neural networks

The German Research Center for Artificial Intelligence (DFKI), based on its experience in the field of machine learning, takes over a large part of the improvement of the data quality through new signal processing steps to be explored using deep neural networks. These learning methods require a large representative database, which otherwise would be very costly to fully cover with real data. The effect of multipath propagation in radar measurement should be recognized and compensated by machine learning techniques. The measured data of the radar sensor are analyzed by means of neural networks and then incorrect values are removed.

Exemplary representation of the vehicle environment detection by Lidar (top left),

Radar (top right) and camera (bottom)

Contact:

Press contact:

Boilerplates:

Astyx GmbH

BIT Technology Solutions GmbH

DFKI